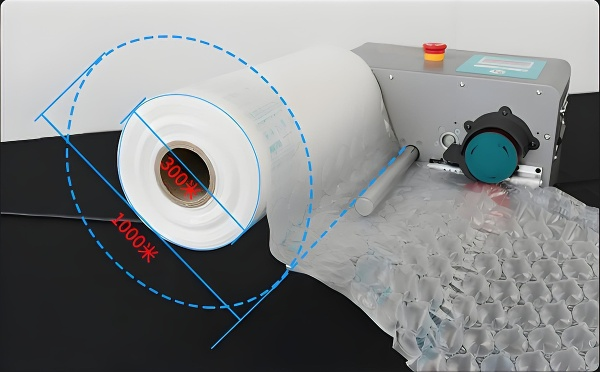

The air cushion machine consists of four main components: film conveying system, air injection device, heat sealing unit, and control system. PE/PP plastic film rolls enter the forming area through guide rollers, while air pump assemblies precisely inject compressed air between film layers. The heat sealing device permanently seals air chambers through temperature control.

Working Process

1.Film Unwinding: Double-layer films are conveyed parallelly after tension adjustment

2.Air Injection: Forming independent air chambers through precision valves at 0.2-0.5MPa

3.Heat Sealing: Transverse sealing by heated rollers at 120-180℃

4.Cooling: Water cooling system stabilizes air chamber structure

5.Cutting: Longitudinal cutting according to preset dimensions

Technical Features

1.Aerodynamic Design: Precisely calculated air chamber volume-pressure ratio ensures 25%-40% elastic deformation space

2.Material Engineering: Triple-layer co-extruded film (wear-resistant outer layer/barrier middle layer/sealable inner layer)

3.Smart Control: PLC system monitors air pressure and temperature with ≤±1.5% tolerance

Applications

Widely used in electronics (anti-static type), medical cold chain (low-temperature resistant type), and art transportation (high-cushion type). Advanced models now offer adjustable air chamber diameters (0.5-50mm) with over 75% energy absorption efficiency.