1. Define Production Requirements

(1).Speed:

E-commerce: 15-25m/min mid-speed models

Industrial: 40-60m/min high-speed models (with dual sealing)

(2).Material Compatibility:

Standard: PE/PP films (0.03-0.12mm thickness)

Special: Anti-static film (≤10^11Ω) or cryogenic film (-40℃ operable)

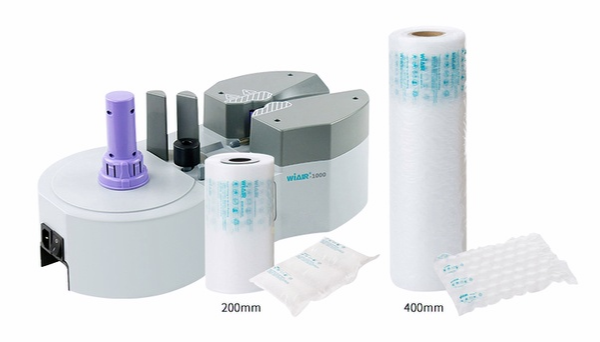

(3).Cushion Type:

Standard bubbles: 5-15mm diameter (general purpose)

Reinforced columns: 30kg/m² capacity (heavy cargo)

2. Core Technical Specifications

| Parameter | Basic | Premium |

| Pressure Control | ±3% | ±0.5% (Servo) |

| Temp Stability | ±5℃ | ±1℃ (PID Control) |

| Energy Efficiency | ≤1.5kW·h/100m³ | ≤0.8kW·h/100m³ |

| Noise Level | ≤75dB | ≤65dB (Silent) |

3. Smart Features

(1).IoT Module:

Material monitoring (±3m accuracy)

Fault alerts via WeChat/Email

(2).Auto-Adaptation:

Film thickness detection (0.02mm precision)

Dynamic pressure adjustment (0.1-0.8MPa)

(3).Data Tracking:

20,000+ hours production logs

Energy consumption analytics